This topic gives a short descriptions about PIC12F1822 microcontroller ADC and PWM module and how to use them using CCS PIC C compiler. For more details go to PIC12F1822 datasheet.

PIC12F1822 ADC Module:

PIC12F1822 microcontroller has a 10-bit ADC (Analog-to Digital Converter) module. 4 Pins can be used as analog inputs which are: RA0 (AN0), RA1 (AN1) RA2 (AN2) a,d RA4 (AN3).

The ADC module is used to read analog data comes from analog devices like analog potentiometer and analog temperature sensors ......

The ADC converts analog data into 10-bit digital data which is stored into the ADC result registers (ADRESH:ADRESL register pair).

The following CCS C line is used to configure PIC12F1822 ADC module:

setup_adc(int16 mode);

Where mode is the source of the conversion clock (ADC clock source). There

are seven possible clock options:

• FOSC/2

• FOSC/4

• FOSC/8

• FOSC/16

• FOSC/32

• FOSC/64

• FRC (dedicated internal oscillator)

CCS PIC C compiler uses the following constants for the previous parameters (used with setup_adc():

ADC_CLOCK_DIV_2

ADC_CLOCK_DIV_4

ADC_CLOCK_DIV_8

ADC_CLOCK_DIV_32

ADC_CLOCK_DIV_16

ADC_CLOCK_DIV_64

ADC_CLOCK_INTERNAL

And to turn off the ADC use the following constant:

ADC_OFF

Example:

setup_adc(ADC_CLOCK_DIV_4);

The following line is used to configure a digital pin as analog:

setup_adc_ports();

The following constants are used in the previous function:

sAN0 // Configure AN0 as analog

sAN1 // Configure AN0 as analog

sAN2 // Configure AN0 as analog

sAN3 // Configure AN0 as analog

NO_ANALOGS // All pins are configured as digital

ALL_ANALOGS // All pins are configured as analog

Example:

setup_adc_ports(sAN1); // Configure AN1 as analog

setup_adc_ports(sAN0 | sAN3); // Configure AN0 and AN3 as analog

To read analog data the analog channel must be selected first using this line:

set_adc_channel(int8 channel);

Where channel can be: 0, 1, 2 or 3.

Example:

set_adc_channel(2); // Select analog channel 2

And to read data use the following line:

read_adc();

PIC12F1822 PWM module:

PIC12F1822 microcontroller has 1 ECCP module (Enhanced Capture/Compare/PWM) which allows us to generate Pulse-Width Modulation (PWM) signals.

The PWM period is specified by the PR2 register of Timer2. The PWM period can be calculated using the following equation:

PWM period = [(PR2) + 1] • 4 • Tosc • (TMR2 Prescale Value)

And the PWM frequency is defined as 1/[PWM period].

PR2 is Timer2 preload value,

Tosc = 1/(MCU_frequency)

TMR2 Prescale Value can be 1, 4, 16 or 64.

For example forPR2 = 255 , microcontroller frequency = 8MHz and Prescale = 16 we get a PWM frequency of 488Hz.

The CCS Timer2 configuration has the following form:

setup_timer_2(mode, period, postscale);

where: mode is TMR2 Prescale Value, period is PR2 and postscaler is not used in the determination of the PWM frequency (keep it 1).

Previous example gives the following Timer2 configuration command:

setup_timer_2(T2_DIV_BY_16, 255, 1);

The PWM resolution determines the number of available duty cycles for a given period. For example, a 10-bit resolution will result in 1024 discrete duty cycles, whereas an 8-bit resolution will result in 256 discrete duty cycles.

The maximum PWM resolution is 10 bits when PR2 is 255. The resolution is a function of the PR2 register value as shown by the following equation:

Resolution = log[4 * (PR + 1)]/log(2)

The following line is used to set the PWM signal duty cycle:

set_pwm1_duty(i);

Where i is an int16 number.

We can change the output pin of the PWM signal and we can select between RA2 pin or RA5 pin respectively using the following two line where the first one is default:

setup_ccp1(CCP_PWM | CCP1_A2); ( Same as setup_ccp1(CCP_PWM ); )

setup_ccp1(CCP_PWM | CCP1_A5);

PIC12F1822 ADC + PWM example:

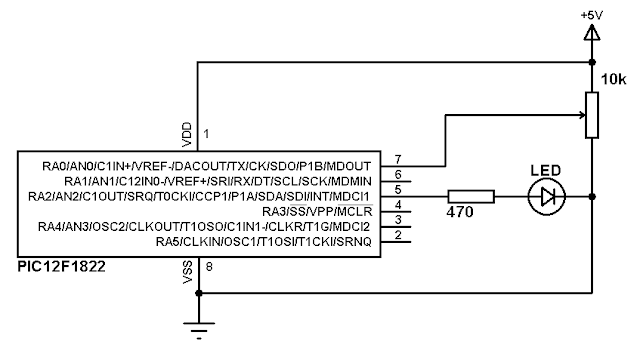

This example shows how to use the digital value of the analog reading to set the duty cycle of the PWM signal. This example uses analog channel AN0 and the ECCP module to control the brightness of an LED connected to RA2 as shown in the following circuit schematic:

PIC12F1822 Internal oscillator is used and MCLR pin function is disabled in this project.

PIC12F1822 ADC + PWM example CCS C code:

PIC12F1822 internal oscillator is used @ 8MHz and PLL is enabled which gives a microcontroller frequency of 32MHz.

Timer2 is configured to generate 1.95KHz PWM signal with a resolution of 10-bit.

// PIC12F1822 ADC & PWM example CCS PIC C code // http://ccspicc.blogspot.com/ // electronnote@gmail.com // Use at your own risk #include <12F1822.h> #fuses NOMCLR INTRC_IO PLL_SW #device ADC = 10 #use delay(clock=32000000) int16 i; void main() { setup_oscillator(OSC_8MHZ | OSC_PLL_ON); // Set internal oscillator to 32MHz (8MHz and PLL) setup_adc(ADC_CLOCK_DIV_32); // Set ADC conversion time to 32Tosc setup_adc_ports(sAN0); // Configure AN0 pin as analog set_adc_channel(0); // Select channel AN0 setup_ccp1(CCP_PWM); // Configure CCP1 as a PWM setup_timer_2(T2_DIV_BY_16, 250, 1); // Set PWM frequency to 1.95KHz with 10-bit resolution while(TRUE){ i = read_adc(); // Read from AN0 and store in i set_pwm1_duty(i); // Set pwm1 duty cycle delay_ms(10); // Wait 10 ms } }

Reference:

PIC12F1822 Datasheet