PIC16F877A RC-5 decoder

The RC-5 protocol was developed by Philips in the late 1980s as a semi-proprietary consumer IR (infrared) remote control communication protocol for consumer electronics.

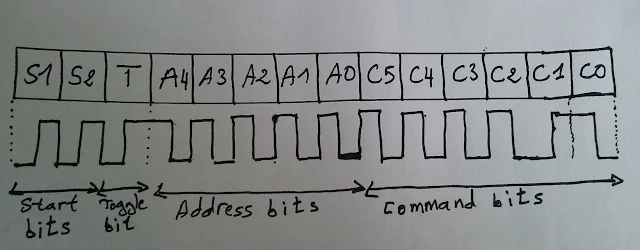

The RC5 has 14 bits per 1 code transmission, the 14 bits can be divided into 4 parts:

The first 2 bits are start bits and they are always logic 1.

The third bit called toggle bit, it can be logic 1 or logic 0.

The next 5 bits are address bits, each device type has its address number for example TV address number is 0, CD player address = 20 ............

And the last 6 bits are command bits, each button has its command number.

For the same device for example TV all the remote control buttons has the same address but each button has its command.

The toggle bit changes whenever a button is pressed.

The RC5 protocol uses Manchester coding, logic 1 and logic 0 are coded as shown in the following drawing where toggle bit is 1, address = 0 and command is 2:

This link from Wikipedia has more details about Philips RC5 protocol.

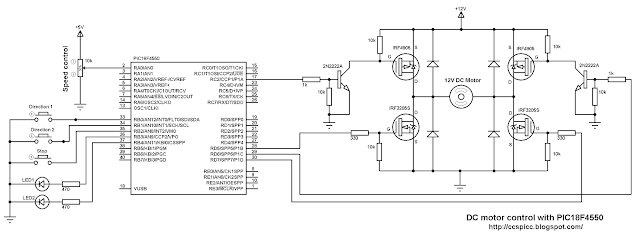

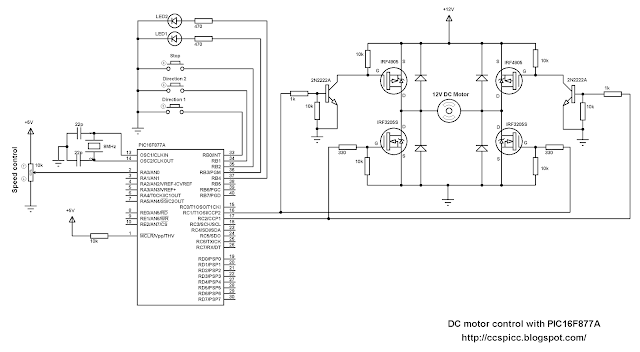

RC5 IR remote control protocol decoder using PIC16F877A microcontroller: This topic shows how to decode and get RC5 data of a TV remote control uses RC5 protocol with PIC16F877A microcontroller and CCS PIC C compiler.

The project circuit schematic is shown below.

The IR receiver is used to receive the IR signals transmitted from the remote control and convert this signals to a digital data (logic 0, logic 1). The microcontroller PIC16F877A reads digital data from the IR receiver, this data is decoded and the results displayed on 1602 LCD display. The LED which is connected to RB1 pin blinks when RC5 protocol is received.

The following drawing shows how the IR receiver receive and transmit data to the microcontroller:

RC5 IR remote control protocol decoder using PIC16F877A CCS PIC C code:

The code is written and compiled with CCS C compiler.

I made the code simple as I can, no Timer module and no interrupt are used.

The microcontroller waits until the IR receiver receives IR data which means it waits until RB0 pin goes from high to low.

The 2 start bits are used to check if the received IR signal uses RC5 protocol. Each bit is 1778us long. The fist start bit is 1 which means it is 0 for 889us and 1 for 889us, the first 889us is not detected because RB0 not triggered yet and the second 889us is detected using the following code:

while((input(PIN_B0) == 0) && (count < 20)){

count++;

delay_us(50);}

if( (count > 20) || (count < 14))

goto ret;

The signal is checked every 50us and a variable (count) is used to count number of 50s, for example if count = 5 so the total time before RB0 goes high is 250us.

If count >= 20 it means time out and the received signal is high for more than 889us.

If count < 14 it means signal high time is lower than 889us.

The second start bit is checked using the following code:

// Check first 889us

while((input(PIN_B0)) && (count < 20)){

count++;

delay_us(50);}

if( (count > 20) || (count < 14))

goto ret;

// Check 2nd 889us

count = 0;

while((input(PIN_B0) == 0) && (count < 40)){

count++;

delay_us(50);}

if( (count > 40) || (count < 14)) // Signal doesn't use RC5 protocol

goto ret;

if(count > 30)

delay_us(400);

else

delay_us(1200);

Second bit checking is the same as the first bit checking except that low both 889us are checked.

After the 2nd start bit there is toggle bit which is 1 or 0, and if toggle bit is 0 time required for RB0 pin is 1778us which means to start reading bits we have to add a delay about 400us, and if the toggle bit is 1 we have to wait 1200us.

The following drawing shows the 2 start bit with toggle bit when it's 0 and when it's 1:

And the following drawing shows when the microcontroller reads the RC5 bits:

The complete RC5 decoder CCS C code is as the following below.

// RC5 remote control protocol decoder using PIC16F877A

// http://ccspicc.blogspot.com/

// electronnote@gmail.com

//LCD module connections

#define LCD_RS_PIN PIN_C0

#define LCD_RW_PIN PIN_C1

#define LCD_ENABLE_PIN PIN_C2

#define LCD_DATA4 PIN_C3

#define LCD_DATA5 PIN_C4

#define LCD_DATA6 PIN_C5

#define LCD_DATA7 PIN_C6

//End LCD module connections

#include <16F877A.h>

#fuses HS,NOWDT,NOPROTECT,NOLVP

#use delay(clock = 8000000)

#include <lcd.c>

#use fast_io(B)

int1 toggle;

unsigned int8 count, i, address, command;

void main(){

port_b_pullups(TRUE); // Enable PORTB pull-ups

output_b(0); // PORTB initial state

set_tris_b(1);

lcd_init(); // Initialize LCD module

lcd_putc('\f'); // LCD clear

lcd_gotoxy(3, 1); // Go to column 3 row 1

lcd_putc("RC5 protocol");

lcd_gotoxy(5, 2); // Go to column 5 row 2

lcd_putc("decoder");

while(TRUE){

ret:

count = 0;

output_low(PIN_B1);

while(input(PIN_B0)); // Wait until RB0 pin falls

// Check if the received signal uses RC5 protocol

while((input(PIN_B0) == 0) && (count < 20)){

count++;

delay_us(50);}

if( (count > 20) || (count < 14)) // Signal doesn't use RC5 protocol

goto ret; // Return

count = 0;

while((input(PIN_B0)) && (count < 20)){

count++;

delay_us(50);}

if( (count > 20) || (count < 14)) // Signal doesn't use RC5 protocol

goto ret; // Return

count = 0;

while((input(PIN_B0) == 0) && (count < 40)){

count++;

delay_us(50);}

if( (count > 40) || (count < 14)) // Signal doesn't use RC5 protocol

goto ret; // Return

// End check (The received signal uses RC5 protocol)

if(count > 30)

delay_us(400);

else

delay_us(1200);

output_high(PIN_B1); // Toggle RB1 LED

for(i = 0; i < 12; i++){

if(i == 0){

if(input(PIN_B0) == 1) toggle = 0;

else toggle = 1;

}

else {

if(i < 6){ //Read address bits

if(input(PIN_B0) == 1)

bit_clear(address, (5 - i)); //Clear bit (5-i)

else

bit_set(address, (5 - i)); //Set bit (5-i)

}

else { //Read command bits

if(input(PIN_B0) == 1)

bit_clear(command, (11 - i)); //Clear bit (11-i)

else

bit_set(command, (11 - i)); //Set bit (11-i)

}

}

delay_us(1778);

}

// Display results

address &= 0x1F;

command &= 0x3F;

lcd_putc('\f');

lcd_gotoxy(2, 1);

lcd_putc("Toggle bit:");

lcd_gotoxy(1, 2);

lcd_putc("Adds:");

lcd_gotoxy(9, 2);

lcd_putc("Cmd:");

lcd_gotoxy(14, 1);

printf(lcd_putc,"%1u",toggle);

lcd_gotoxy(6, 2);

printf(lcd_putc,"%2u",address);

lcd_gotoxy(14, 2);

printf(lcd_putc,"%2u",command);

}

}

RC5 IR remote control protocol decoder using PIC16F877A video:

The following video shows the project using hardware circuit with some details.